Print Quality Inconsistencies

Why Your Book Looks Perfect Today and Different Tomorrow

This is one of the most painful truths of Print-on-Demand, and most authors are never warned about it.

You order a proof.

It looks great.

You approve it.

Weeks later, a reader sends a photo. The colors look different. The paper feels thinner. The blacks are less rich. Nothing is wrong, but nothing is exactly the same either.

That is not carelessness. That is how POD actually works.

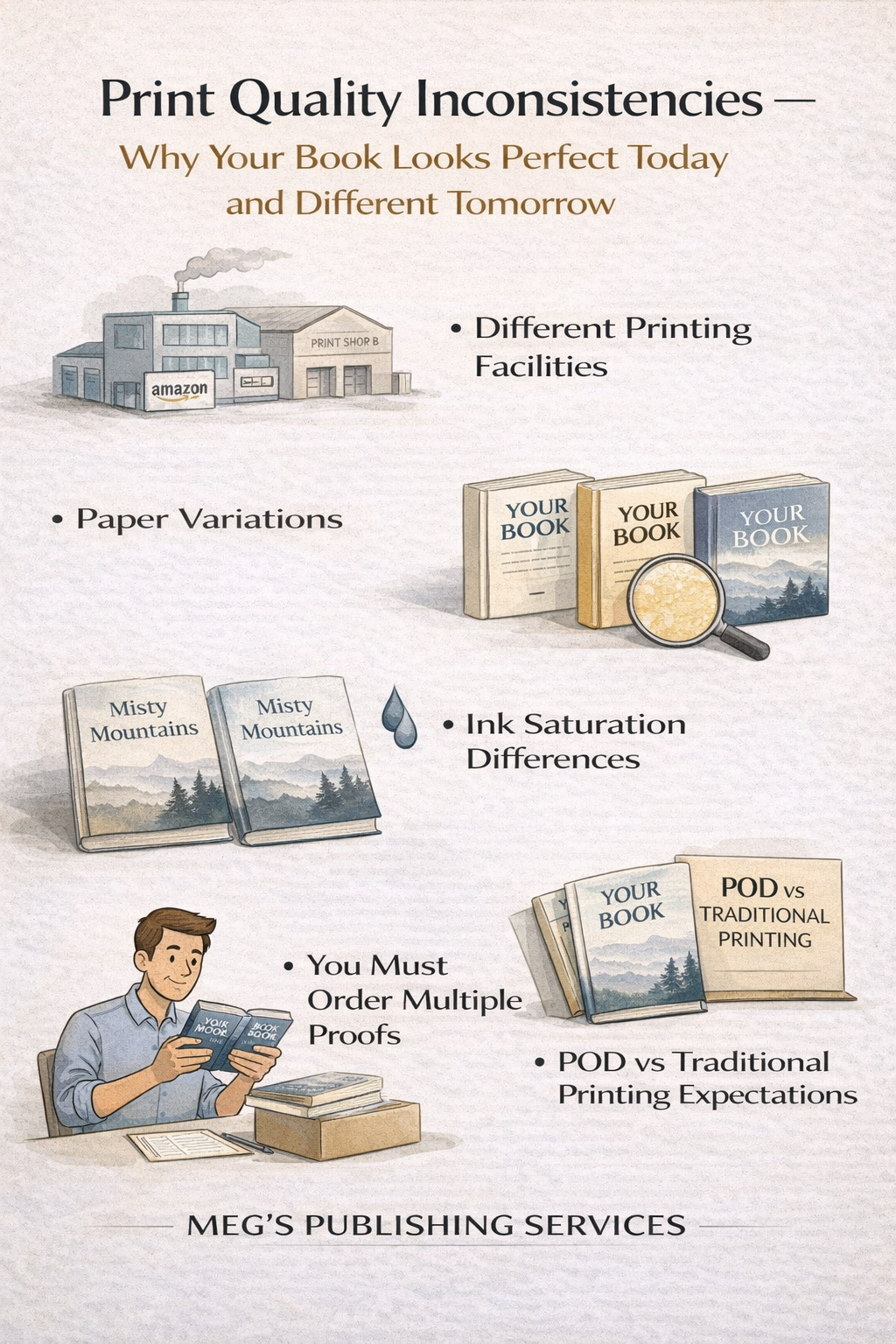

Different Printing Facilities, Same File

POD is decentralized. Your book is not printed in one factory forever. It is routed automatically to different printing facilities based on location, demand, capacity, and logistics. Each facility uses equipment calibrated within acceptable ranges, not identical settings.

The file is the same. The machines are not.

This alone explains why two copies printed weeks apart can look slightly different.

Paper Variations Are Normal

POD platforms source paper regionally. Paper weight, texture, brightness, and coating can vary between suppliers while still meeting platform specifications. That means one batch may feel smoother, another slightly rougher. One may appear brighter, another warmer.

These differences are within tolerance.

They are not defects.

Authors expecting perfect uniformity are applying traditional print expectations to an automated system that is built for scale, not sameness.

Ink Saturation Is Not Fixed

Ink behaves differently depending on paper stock, humidity, press calibration, and print speed. Deep blacks, gradients, and dark colors are most affected. One copy may appear richer, another slightly muted.

POD prioritizes legibility and consistency within ranges, not museum-level color matching.

Designs that rely on heavy ink saturation will show variation more clearly than restrained, print-aware designs.

Why Ordering One Proof Is Not Enough

One proof tells you how the book can look.

It does not tell you how the book will always look.

Professional standards require ordering multiple proofs, ideally spaced across time or printed from different locations when possible. This reveals how resilient your design is under real POD conditions.

If a design falls apart with small variations, the design is the problem, not the printer.

POD Expectations vs Traditional Printing

Traditional offset printing is centralized. One press. One paper batch. One controlled run. Consistency is the product.

POD is distributed. Automated. Scalable. Consistency is managed within tolerance, not precision-matched.

Expecting POD to behave like offset printing creates frustration. Understanding the difference creates peace and better decisions.

Authors who design with POD realities in mind experience fewer surprises and fewer complaints.

Why This Reality Builds Trust, Not Fear

Readers rarely compare two random copies side by side. They notice quality only when it is poor, not when it is slightly different.

Books built with:

Conservative color choices

Strong contrast

POD-friendly layouts

Print-aware finishes

Hold up well across facilities and time.

Books built without that awareness expose every variation.

Final Thought

If your POD book looks perfect today and slightly different tomorrow, that does not mean something went wrong. It means the system is working as designed.

The goal is not perfection.

The goal is resilience.

If you want your book designed to survive real-world POD printing, not just look good in one proof, Meg’s Publishing Services builds with those standards from the start.